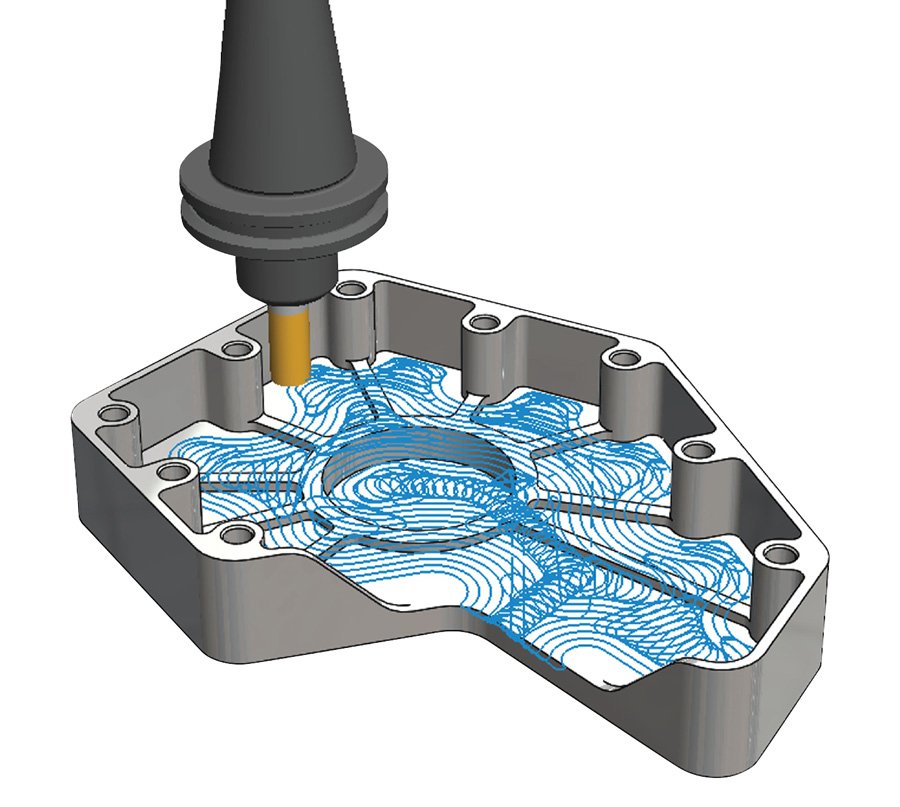

Production manager Tirath Singh speaks highly of CAMWorks’ performance with TECMA’s new CNC machining centers. CAMWorks met TECMA’s goals of modernizing, increasing efficiency and improving quality.

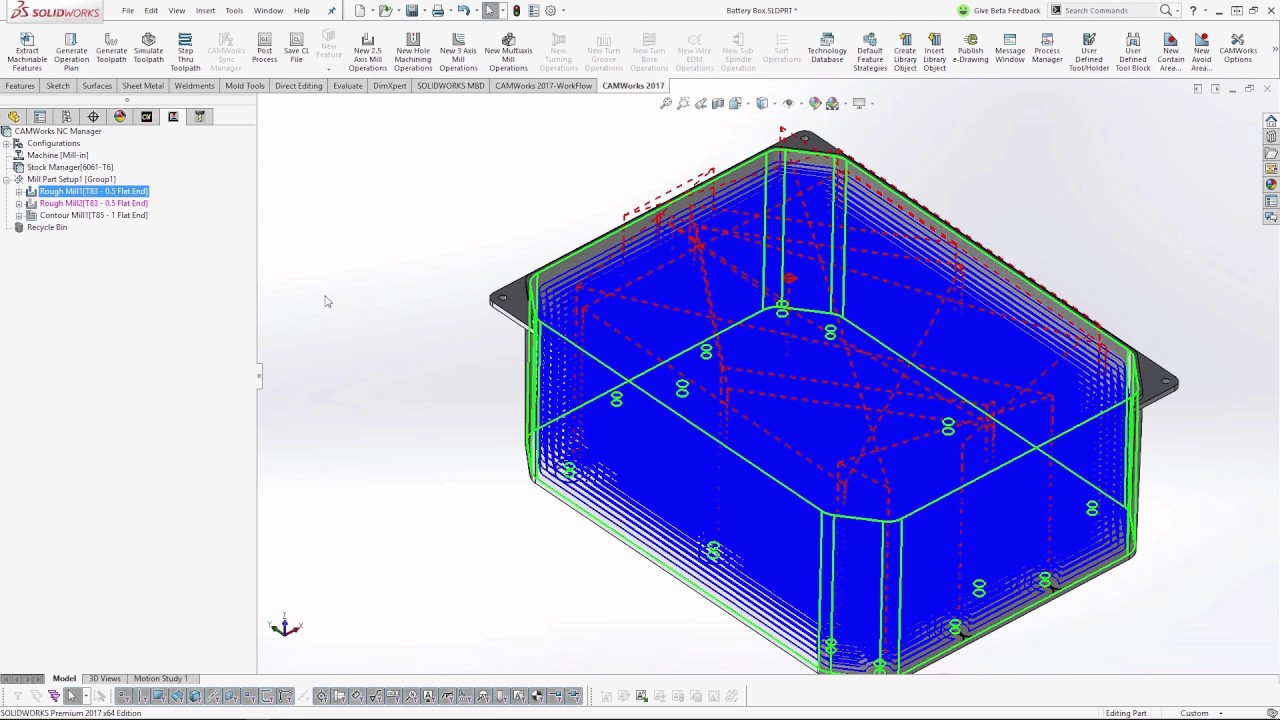

Investing in automated CNC machining centers with five-axis machining capabilities, as well as a software system to automate digital machining operations, would enable the company to compete for new business. It also had a small employee base with only 2D programming experience. When Susac inherited the company, it had only two CNC machines to nearly 20 manual machines. Part of that was to obtain some important certifications - such as AS9100 Quality Management Systems, ITAR, and cybersecurity compliance - in order to remain competitive and grow.” A Manual Overhaul “While TECMA had and still has a great reputation in the aerospace and defense industries, we needed to expand our customer base and update our compliance to NASA and Department of Defense requirements. “When my father passed away and I took over management, I quickly realized that we needed to re-tool and modernize to continue to be successful,” Susac says. She recognized that keeping the company competitive required a transition from 2D programming and manual machining to 3D digital production. Schwarz led TECMA until his passing in 2012, after which his daughter Sonia Susac took ownership. The company was founded by Fred Schwarz and his partner Alfred Nohr in 1957. The company specializes in CNC and conventional precision machining for hard-to-manufacture, mission-critical components, but this specialization has required evolution over the years. defense contracts as well, and has recently expanded into producing parts for carbon-negative energy systems. The company has supplied parts for many U.S. has long provided precision machining services for the aerospace and defense industries. Images courtesy of TECMA.įrom the Apollo 11 lunar lander module to today’s Artemis missions, TECMA Inc. She spearheaded the shop’s transition to 3D digital machining and ensured it had the certifications and qualifications to continue providing precision parts for everything from carbon-negative energy systems to critical parts for the Artemis space missions. Sonia Susac is the second-generation owner of TECMA Inc.

0 kommentar(er)

0 kommentar(er)